The grinding / sharpening of punchcut V-shape knives is not a straight forward operation !

It can quickly become a nightmare for a grinding station, in particular if there are nicks and breaches on the cutting bevels. Indeed, one cannot say that the regrinding operation of V-shape knives is an industrial process under its current state of the art : it requires a special grinding wheel, it is time consuming compared to other knives, it is difficult to make it a cost effective work.

At end-users level, the feeling is quite the same : when there is a problem at the trimming stage, it is most of the time because the punchcut V-shape knife is not doing the job the way it should when it comes back from regrinding.

Because our company C&LUI is both a grinding station and a knife manufacturer, it has developped a solution for V-shaped knives that brings satisfaction to regrinders and consequently to end-users :

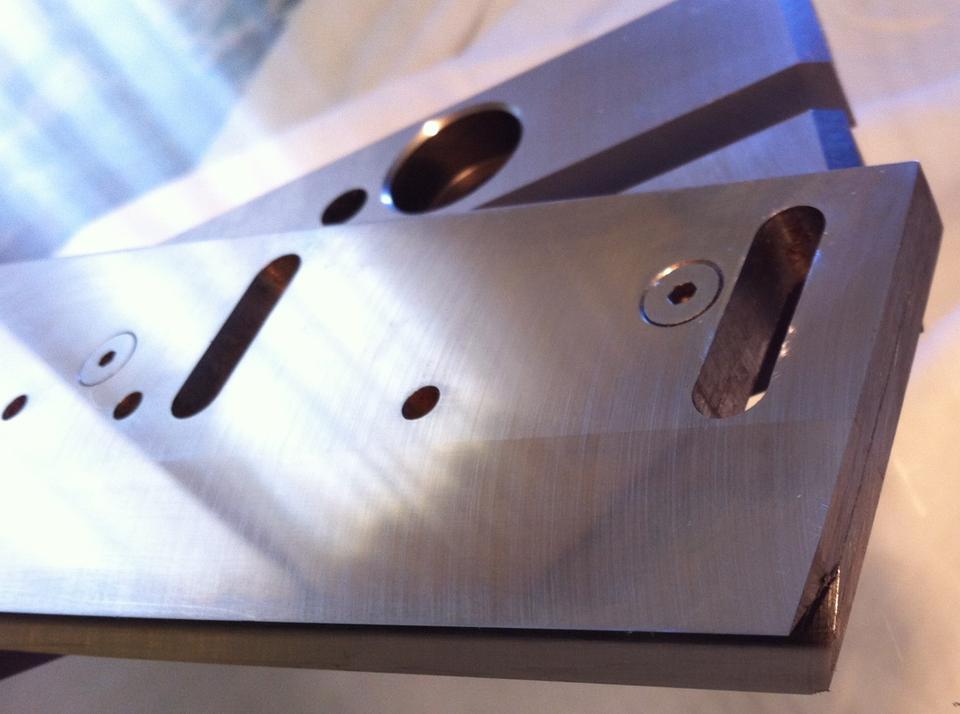

the punchcut V-shape knife made of 2 assembled parts

The underlying questions of the project were :

- how can we industriaze the sharpening process of V-shape knives

- how can we bring complete satisfaction to end-users

- how can we make it universal

Very often good ideas are simple ideas.What answers the above questions all together is a V-shape knife which is made of 2 parts that can be disassembled for grinding purpose and re-assembled for end-using purpose. In addition, it becomes possible to manufacture such knives with an HSS tip ( or even a TCT tip ), which means an increase in the longevity of the cut.

The principle of 2 assembled parts is now available for all makes of V-shape knives.

Call us on (33) 1 34 86 13 90

or use contact form on http:// www.c-et-lui.com

Whether you are a regrinder or a bookbinder, bear in mind that our principle of the punchcut V-shape knife in 2 assembled parts is the solution that solves all your problems :

- at grinding station level : at last it becomes possible to sharpen these knives on an industrial basis with a standard grinding machine and with usual grinding wheels.

- at trimming operation level : at last a V-shape knife that shows a good longevity of cut, with no discrepancy in the heigth of the 2 bevels or wrong bevel angle, paper strips do not pile up inside the V , and it opens new possibilities about the thickness that can be cut under such a knife.

- you are an end-user of splitcut V shape knife, are you satisfied with the current state of the art ?

- you are a sharpening workshop, do you think the above described device could help you to industrialize the regrinding process of V-shaped knives ?

- All comments are welcome.